Vertical Pouch Filling Machine Applications In Practices

Using a vertical pouch filling machine for your small business can be a great way to save money on your packaging and make your business run smoothly. But, it’s not just the machine that’s important. You’ll also need the right tools and supplies to help you get started.

Part 1. Automatic Vertical Wheat Flour /Wheat Powder Packaging Machine

Because of the ” epidemic ” influence , many people stay at home to cook all kinds of food , facing the upsurge of making rice cooker cake online , many people also follow the trend to make cake , making cake needs to use flour . Therefore , the supply of bagged flour on the market is in short supply , and the factory does not have so many workers to put into production immediately.

The semen Tritici Aestivi is rich in starch, protein, fat, mineral, calcium, iron, etc., and has rich nutrition. it can be ground into flour to make bread, biscuit, steamed bread, etc., or ferment to make beer and alcohol.

The vertical wheat flour automatic packaging machine has been delivered to Russia. The operation video and online guidance on how to operate the wheat flour packaging machine have been sent to customers. It has been put into production and use. The packaged wheat flour is automatically packaged at one time from conveying, metering, bag making, filling, date printing, sealing, cutting and product output. The packaging speed of 500g is 42 bags per minute, 2520 bags per hour and 20160 bags per 8 hours. Far beyond the speed of several manual packages. If you need to pack small grams of wheat flour, such as 30-100 grams, we recommend the small vertical wheat flour packing machine to you, the following is the small wheat flour packing machine.

Part 2. Automatic Vertical Washing Powder/Detergent Powder Packaging Machine

Washing powder is essential in our daily life, especially for cleaning clothes. Washing powder is divided into two categories, one is ordinary washing powder, and the other is industrial washing powder. Ordinary washing powder is characterized by low density, strong viscosity and weak flow. Industrial laundry detergent has a high density, good fluidity, and is relatively dry. These two kinds of washing powder can correspond to two different automatic washing powder /detergent Powder packaging machines.

1. Volumetric cup type automatic washing powder/detergent Powder packaging machine. The volumetric cup is customized according to the density and volume of the washing powder, so if the customer chooses the automatic washing powder packing machine with volumetric cup , the customer must provide us with the density of the washing powder, and our designer will customize the measuring cup according to the density of your washing powder. The volumetric cup is generally able to pack small-gram laundry detergent, for example, in the range of 20-300g. The following is the volumetric cup automatic detergent Powder packaging machine.

2. Linear weighing fully automatic washing powder packaging machine. The customer also provides the density of the washing powder, and we recommend different linear scales. Linear scales are divided into two-head linear scales and four-head linear scales.

Industrial laundry detergent has a high density, good fluidity, and is relatively dry. A screw-type automatic laundry detergent packaging machine is recommended. The screw type automatic detergent Powder packaging machine obtains the target weight by adjusting the number of turns of the screw.Screw-type automatic washing powder packaging machine, if you need to pack washing powder within 100 grams, we will recommend you a small automatic washing powder packing machine, the model is SK-320F, and the largest bag size is 150*300mm. More than 300 grams of laundry detergent, we will recommend a large automatic laundry detergent powder packaging machine.

Part 3. How To Make Your Gel Ice Bag ?

In our life and application, there are many products that need frozen transportation. In addition to cold chain freezer transportation, ice bags will be used for small cargo transportation, which can also play a role in refrigerated transportation, and can maintain a continuous low temperature environment for products. Reduce deterioration and damage of products during transportation.

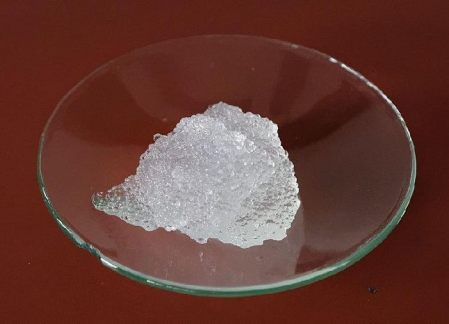

Do you know what gel ice bags are made of? How do you pack this frozen gel ice bag? In fact, the product for making frozen gel ice bags is a kind of powder, called Super Absorbent Polymer (SAP), which is a new functional polymer material. It can absorb water hundreds to thousands of times heavier than itself, and has excellent water retention performance. Once the water swells into hydrogel, it is difficult to separate water even under pressure. The hydrogel is metered and packaged with a liquid packaging machine. After being packaged into bags, it can be frozen to become bags of frozen gel ice. This can be applied in many places.

The use of industrial absorbent resin gel ice packaging bags in the field of packaging and transportation is also of great use. The food that may be damp or overflow during transportation and storage can be packed with composite materials containing super absorbent resin to ensure its safety. The super absorbent resin is packaged into bags with liquid packaging machine to transport meat food, seafood, frozen fresh food, fruit and juice, etc., which can keep the food clean, keep the food fresh and improve the commodity value. In medical treatment, gel ice packs are mainly used to cool and reduce fever, diminish inflammation and pain, and to supplement physical therapy with cold packs for beauty, sprain, hemostasis, suppuration, skin care, etc.

Machine Used For Water Absorbent Resin Gel Ice Packaging

The water absorbing resin shall be proportioned in the proportion of 2:98 or 1:100 to obtain water absorbing gel with different consistency. After stirring, the liquid gel will be in a uniform state. The fluidity of the liquid gel in such a uniform state is still good, and the liquid does not have too much viscosity. It is a relatively good liquid. We can use the pneumatic liquid pump to measure and cooperate with the packing machine for full-automatic liquid gel packing. According to my previous packaging cases, our customers in Australia and the United States have different weight and proportion of packaging, so we can adjust the weight of packaging according to the market demand of our products. The automatic liquid gel packaging machine mainly packs 400-800g frozen gel bags per bag. The bag is small and convenient to use in many industries.

What Roll Film Material Is Used To Package Absorbent Resin Gel ?

Water absorbing resin gel packaging bags are generally made of composite film material NY/PE, or PE/PE. The roll film of NY/PE is a composite film, and the price of the material is relatively higher than that of PE/PE. The relative price of PE/PE roll film will be lower, but the sealing device of the packaging machine is relatively complicated. If you choose PE/PE roll film, you can actually save a lot of roll film costs. Therefore, many customers will choose the roll film with this feature.

How Fast Is The Packing Speed of Absorbent Resin Gel ?

Absorbent resin liquid gel packaging machine, for 400-800g packaging, if the PE/PE film is used, the speed is about 18-25 packages/minute. The weight of gram is light and the bag is short, so the packaging speed is faster. If the bag is large, the packing speed will be relatively slow. If the composite film NY/PE material is used, the packaging speed will be relatively fast, about 22-28 packages/minute.