Discussions On Automatic Packaging Machines

In the hot summer, adding edible ice cubes to the delicious milk tea will instantly cool the body and mind; for sprained hands and feet, apply medical ice cubes to the sprain to relieve the pain; frozen food items should be stored in ice packs during transportation. The use of ice cubes is very wide, which makes the large-scale automatic ice packaging machines develop rapidly in the packaging machine industry.

1. Do you know how much output you need in a day?

2. How many kilograms of ice do you need to pack?

3. What is the specific bag size?

4. Is the bag PE film or how to composite film?

Features of SK-L720 Vertical Automtaic Ice Packing Machine:

1 Adopt color Chinese and English touch screen and imported PLC control, easy to operate, intuitive and efficient.

2 The pneumatic control and circuit control are independently separated, with low noise and more stable circuit.

3 Using vacuum double-belt servo motor to pull the film: the film pulling resistance is small, high-precision positioning is achieved, the size is accurate, the packaging bag is well formed, more beautiful, and the belt is not easy to wear.

4 Using an external film release mechanism, the packaging film installation is simpler and easier.

5 This machine is matched with the metering device to automatically complete the whole process of feeding, metering, filling bag making, printing date, inflation (exhaust), and finished product delivery

6. Electric horizontal sealing, vacuum film pulling (optional configuration)

7. Equipped with two heads screw weigher and vertical Z-type material elevator, the speed and efficiency are better played.

SOONKPACK Machinery’s large-scale vertical automatic packaging machine for ice particles and ice cubes can pack ice particles, ice cubes, tube ice, etc. in food, medical, health, chemical and other industries. , so that SOONKPACK Machinery’s large-scale vertical automatic packaging machine for ice pellets and ice can maximize the efficiency of professional ice-producing enterprises around the world.

Factors Affect The Speed of The Vertical Particle Combination Weigher Weighing Packaging Machine?

The vertical particle combination weigher weighing packaging machine mainly packs granular material products, such as puffed food, whole grains, nuts roasted seeds and nuts, pet food, hardware screws, toys and other products. Besides, the machine is mainly composed of the packaging machine host, weighing combination weigher and support platform. When we use the vertical particle combination weigher to weigh the quantitative packaging machine, the factors that affect the packaging speed of the packaging machine will be Which are there? Today, SOONKPACK will reveal the secret for you. Here are

1) The small hopper on the combination scale can move up and down, the material with small gram weight will move down, and the material with large weight will move up. The vibration force of the vibrating plate also needs to be large enough. It mainly depends on the number of combined buckets. Generally, it is combined before and after 4 buckets (3, 4, 5), then his accuracy and speed are the fastest.

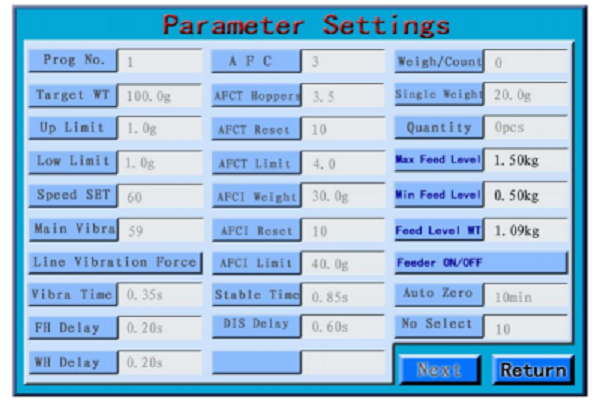

2) Parameter settings on the control screen of the computer combination scale: ①Vibration feeding time ②Linear vibration amplitude ③Stable time ④Auto zero setting time ⑤Feed motor mode, weighing motor mode, aggregate motor mode.

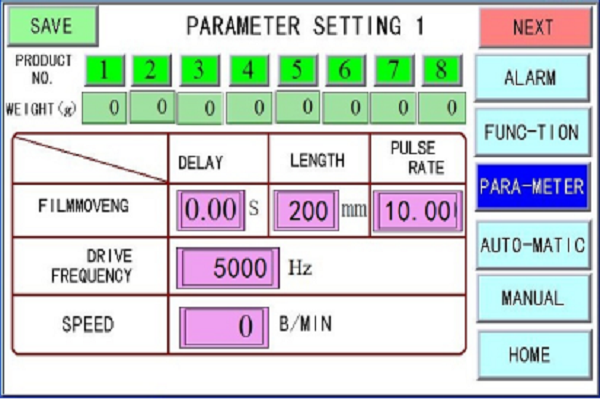

3) Parameters of the main control panel of the packaging machine: ① drive frequency, ② packing speed, ③ bag length, ④ horizontal sealing time, ⑤ vertical sealing time, ⑥ cutter, ⑦ temperature, ⑧ pre-sealing (same parameters, pre-sealing The speed of the seal is very critical, the larger the value, the faster the speed, the smaller the value, the slower the speed)

The above three points are the main factors affecting the weighing and quantitative packaging machine of the vertical particle combination weigher. When adjusting, it needs to be adjusted according to the actual material situation and the thickness of the bag.

Notices For Using The Vertical Granule Packaging Machine?

Vertical granule packaging machines are widely used, and the vertical granule packaging machines we produce are for the packaging of small bags, and the weight range of the packaging is within 10 kg. There are many product models of vertical granule packaging machine, and the selected model is selected and purchased according to the size of the packaged bag.

1) Before each startup, it is necessary to check and observe whether there is any abnormality around the machine;

2 When the vertical granule packaging machine is in operation, it is forbidden for the body, hands, head and hair to contact the working parts;

3) When the vertical granule packaging machine is in operation, it is forbidden to handle or tools to prevent the sealing knife seat, and do not touch the horizontal and vertical sealing rollers with the handle, otherwise it will burn;

4) During the normal operation of the machine, it is forbidden to switch the operation button frequently, and it is forbidden to change the parameter setting value at will;

5) Foreign matter must not be mixed in the packaging process, otherwise it may cause material blocking, inaccuracy or damage to the machine parts;

6) The storage piston of the vertical granule packaging machine and the sealing ring at the lower end of the discharge cylinder need to be replaced in time.

When the vertical granule packaging machine finishes work, we need to clean up the machine, prepare for the next day’s operation, and regularly fill the meshing parts of the gears, the oil filling holes of the bearing with seats and the moving parts of the vertical granule packaging machine. Oil lubrication, when adding lubricating oil, do not drip oil on the transmission flat belt to prevent slippage or accelerate the aging of the belt.