How to adjust the cursor of automatic packing machine

Automatic packaging machines can be divided into three types according to classification: granule packaging machines, powder packaging machines and liquid packaging machines. Automatic packaging machines are also called roll film automatic packaging machines, because the automatic packaging machine requires the use of roll film to form fully automatic packaging.

Generally, when we purchase an automatic packaging machine, we also need to purchase additional consumables – packaging film, so generally our packaging film will have positioning on it. If the photoelectric eye (color identification) is set incorrectly, the positioning point will go astray. The packaged finished product will not have the effect we want. The photoelectric eye of the automatic packaging machine is to identify the positioning point on the packaging film. If the positioning point passes through the printer and there is no response, then the photoelectric eye of the printer will not be able to play its role. So how should we debug when we encounter this problem with the automatic packaging machine? Today kpack Joyce will provide you with a detailed solution to this problem soon.

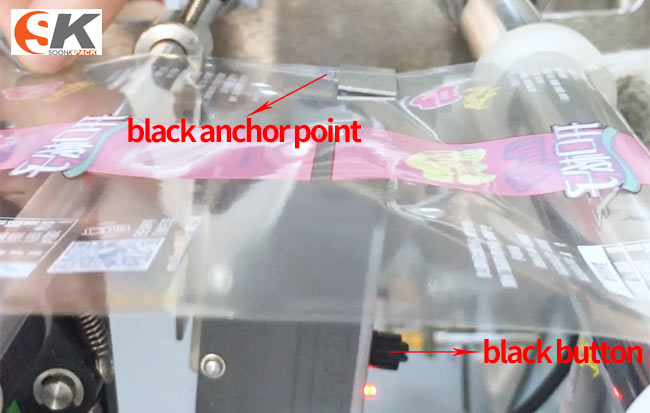

Let’s first take a look at the positioning point pictures of the packaging film:

When we purchase an automatic packaging machine and install a cursor (photoelectric eye), the bag needs to follow the cursor and adjust as follows:

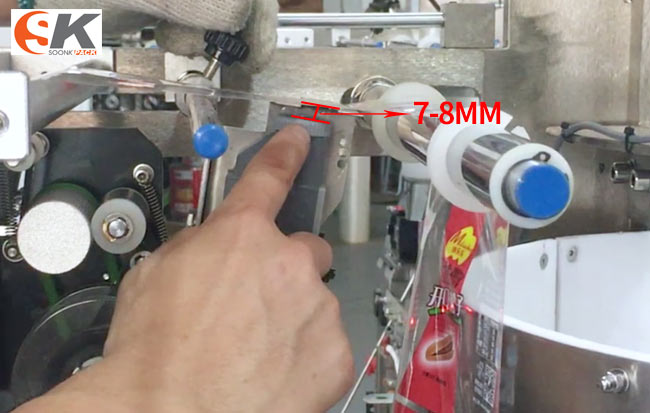

1.First adjust the distance between the photoelectric lens and the packaging film: To adjust their distance, you need to use a screwdriver to loosen the two screws on the photoelectric eye (as shown below). Adjust the distance to about 7-8mm, and then adjust the dots of the photoelectric eye. Try to be as solid as possible;

Then adjust the sensitivity of the cursor (photoelectric eye). When the packaging film is transported, the light will flash when the positioning point of the packaging film passes the cursor. This is normal. Before adjusting the test, you should select the range outside the fixed point (black point) of the packaging film, twist the black button above the cursor (photoelectric eye) (as shown below), twist counterclockwise, the cursor point will turn off (the red light will go out), turn it clockwise Twist, and the cursor point will turn on (the red light will turn on). Generally, when twisting, try to twist 2-3mm to ensure the stability of the cursor. If the twist is too little, the light sensitivity will be too strong. After turning it on, we test whether the positioning point will flash when it passes the cursor. The method is: pull the black positioning point of the packaging film to pass the cursor (photoelectric eye). If the black positioning point flashes red when it passes the cursor, the debugging is successful. If the black positioning point is If the cursor does not flash red when you click it, then the debugging fails and you need to try multiple times!

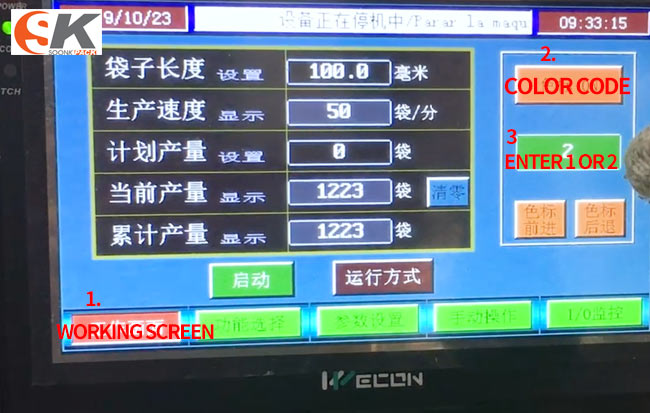

3. Next, set the packaging film and color code, and adjust the data on the display screen of the vertical packaging machine (as shown below)

(1) Working screen – determine the length according to the color scale (open the color scale), the set number is 1 or 2, and cannot be set to 0, after setting;

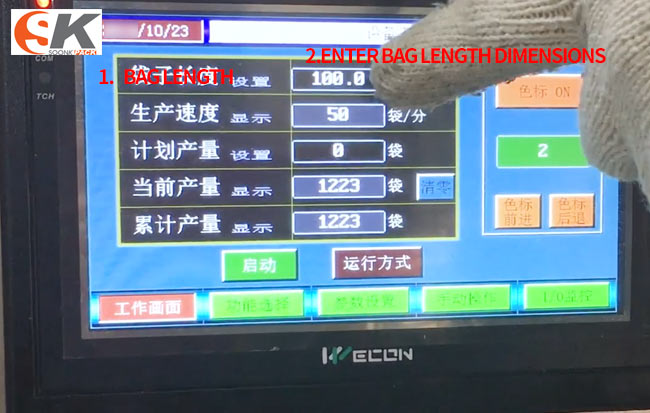

(2) Set the length of the bag. If the distance between the black positioning point of the packaging film on your hand and the black positioning point is 110mm, then when setting the bag length, it should be 5-15mm longer than the actual length, which is 118mm or more. The anti-pull film wheel slips, causing the bag to deviate. After the setting is completed, the vertical automatic packaging machine can be started to test whether the bag follows the cursor.

The following pictures are: successful pictures of the vertical automatic packaging machine adjusting the bag to track the cursor.

The above solution provided by soonkpack is how to adjust the cursor of the automatic packaging machine. If you still don’t know how to operate this, you can contact us. We can provide a video of the operation or directly open a video call for direct teaching. Soonkpack has been focusing on automatic packaging machines for 16 years. R&D and manufacturing, whether you need to know about granule packaging machine, powder packaging machine, liquid packaging machine or fully automatic packaging machine line, we can provide you with professional opinions and suggestions