Robotics and Automation in Modern Packaging Lines

In the ever-evolving world of manufacturing and logistics, the integration of robotics and automation has ushered in a new era of efficiency and precision, especially in the packaging industry. Driven by the relentless pursuit of speed, accuracy and cost-effectiveness, fully automatic packaging lines are currently at the forefront of technological advancement.

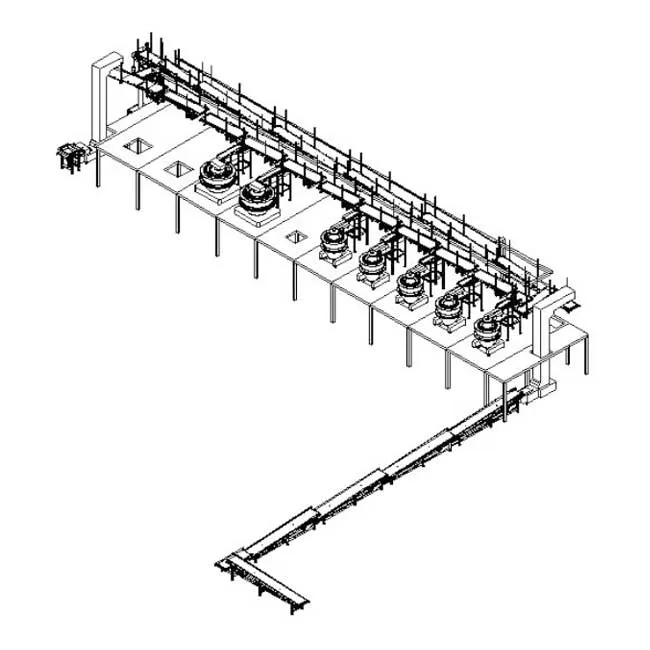

Fully automatic packaging lines represent a remarkable technological advancement in the packaging industry. These complex mechanical and technical components are designed to handle the entire packaging process without human intervention. They include a variety of machines, including filling machines, sealing machines, labeling machines, and robotic systems to automate product placement, filling, sealing, labeling, and quality control.

This article delves into the role of robotics and automation in modern packaging production lines, highlighting the use of robotic arms, pick and place systems and automated quality control to revolutionize the packaging industry.

The Evolution of Packaging Automation

Historically, packaging tasks were labor-intensive, time-consuming, and prone to errors. However, with the emergence of automation and robotics, these limitations have been replaced, ushering in a new era of packaging efficiency.

Robotic Arm and Precision

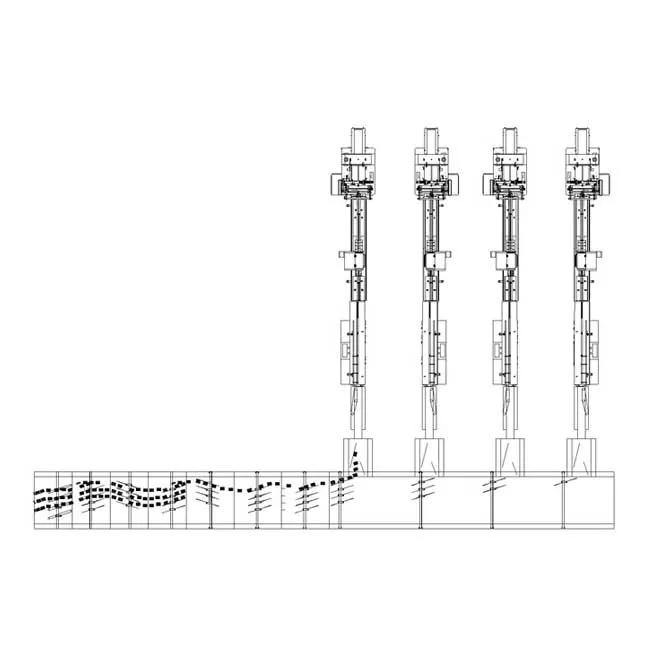

The robotic arm is an important part of the fully automatic packaging line. These mechanical attachments are engineered to replicate human motion with unparalleled accuracy and are used to perform tasks such as picking, placing, and manipulating products, containers, and packaging materials. The dexterity and consistency of the robotic arm transform the packaging process, ensuring every product is packaged with pinpoint precision.

Pick and Place System

One of the most critical advancements in packaging automation is the introduction of pick and place systems. These systems are designed to automate the process of selecting a product or component and placing it precisely at a designated location within a package.

They use specialized end-of-arm tools and cameras to identify, pick, and place items into packages with extremely high accuracy and speed. Pick and place systems are critical for fast, accurate packaging, especially in industries that require high-speed production.

Automated Quality Control

Ensuring the quality of packaged products is crucial, and automation plays a key role in this aspect. Automated quality control systems use sensors, cameras, and machine learning algorithms to inspect products for defects, irregularities, or contamination. They help ensure that only high-quality products are packaged, reducing waste and the risk of recalls.

Advantages of Fully Automatic Packaging Lines

Fully automatic packaging lines offer several advantages, including increased speed and efficiency, reduced labor costs, improved product consistency, enhanced quality control, and the ability to adapt to different packaging requirements quickly. They can also contribute to sustainability efforts by reducing waste and optimizing energy use.

1. Speed and Efficiency

The integration of robots and automation in packaging lines has resulted in significant improvements in speed and efficiency. These advances are particularly important for industries such as food, pharmaceuticals, and e-commerce that require high-speed production and quick turnaround times.

Fully automatic packaging lines have the ability of high-speed packaging. Robotic arms and pick-and-place systems can work at incredible speeds, far exceeding human capabilities. This speed is invaluable in industries that need to package large quantities of products in a short period of time.

Additionally, automation provides consistency and reliability that is difficult to achieve manually. The robotic arm will not experience fatigue or performance changes, ensuring the same quality and appearance for every package. This reliability is especially important in industries with strict quality control standards.

Automated packaging also significantly reduces the need for manual labor. This not only reduces production costs but also resolves labor shortages and related challenges. As a result, manufacturers can allocate labor to more strategic and value-added tasks, while repetitive and physically demanding packaging tasks are handled by automatic packaging machines.

2. Adaptability and Flexibility

Adaptability and flexibility are defining characteristics of automatic packaging lines. Packaging lines can be quickly reconfigured to handle different products, sizes, and packaging requirements. This versatility allows manufacturers to respond to changing market demands and product variations.

Fully automatic packaging lines can easily switch between different packaging formats and product types. Whether resizing boxes, changing label designs, or switching from bottles to cans, they are engineered to enable quick changeovers, thereby minimizing downtime and maximizing overall productivity.

Furthermore, in an era where consumer demand for customized and personalized products is on the rise, packaging automation offers an ideal solution. It can adapt to this trend by allowing variable data printing and labeling. Whether it’s adding personalized messaging, customizing packaging designs, or customizing packaging for different markets, automation can cater to personal preferences at scale.

3. Improve Quality and Consistency

The quality and consistency of packaged products are critical to brand reputation and customer satisfaction. Automation and robotics play a key role in maintaining and enhancing these aspects of packaging.

In industries such as food and beverage, accurate filling and weighing are critical to meet regulatory requirements and ensure the quantity of product in each package. Automatic filling and weighing systems use advanced technology to ensure accuracy, reduce product waste, and ensure compliance with legal standards.

In addition, the introduction of packaging automation can effectively solve the errors that penetrate into the packaging process due to human participation. Whether labeling, sealing, or placing products into packaging, human involvement in the packaging process may introduce potential errors. Automation eliminates many human-related errors, thereby reducing rework and waste. The result is a consistently high-quality end product.

4. Sustainability and Eco-Friendly Packaging

Fully automatic packaging lines can contribute to cost savings and sustainability in many ways. These advantages are becoming increasingly important in today’s competitive and environmentally conscious market.

One of the important ways that fully automatic packaging lines promote sustainable development is through the use of recyclable materials. The environmental impact of packaging can be minimized by using environmentally friendly packaging materials that are easy to recycle or reuse.

Efficient packaging automation minimizes waste by optimizing the use of packaging materials. Precise measurements and reduced errors mean less packaging material is needed, reducing costs and environmental footprint. Sustainable and recyclable packaging materials are also becoming increasingly common on automated packaging lines.

Moreover, fully automatic packaging lines are designed with energy efficiency in mind. The robotic arms and automated machinery are engineered to reduce operating costs and reduce environmental impact. This focus on sustainability is consistent with the global push for green manufacturing practices.

Conclusion

The integration of robotics and automation into modern packaging lines is transforming the industry in profound ways. The benefits they bring range from unprecedented speed and precision to superior adaptability and operational efficiency.

One of the standout features of this transformation is the sheer speed and efficiency achieved through automation. Modern packaging lines are capable of operations at a pace that would be impossible for humans to match. With their high precision and tireless ability, robotic arms can seamlessly handle a variety of tasks, from picking and placing items to filling and sealing packages at incredible speeds.

Additionally, the integration of automation offers a level of precision and consistency. The robotic arms and automated systems maintain a remarkable degree of consistency and reliability, ensuring that each product is packaged with the same level of accuracy and appearance.

As Soonkpack continues to explore the benefits and navigate the challenges of fully automatic packaging lines, we are actively shaping the industry’s future. Adopting these advanced technologies not only has the potential to reduce costs and improve product quality but also helps achieve sustainability goals, aligning our operations with the growing global emphasis on eco-friendly and environmentally conscious practices.